JOURNAL 3128

Records of Agricultural and Food Chemistry

Year: 2024 Issue: 3 Special Issue: Abstracts 3rd. TCS, International Food Chemistry Congress February 29-March 03,2024 Antalya Türkiye

p.43 - 43

Viewed 1327 times.

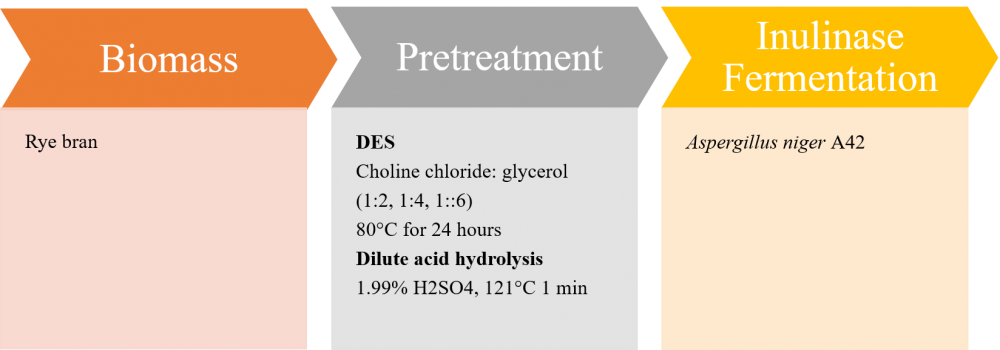

GRAPHICAL ABSTRACT

ABSTRACT

The aim of this study was to produce inulinase enzyme from rye bran (RB) by deep eutectic solvent (DES) pretreatment. RB samples were mixed with choline chloride (ChCl):glycerol (Gly) at different molar ratios (1:2, 1:4, and 1:6) and pretreated at 80°C for 24 hours. The DES pretreated samples were then hydrolysed in an autoclave with 1% H2SO4 at 121°C for 1 minute. RB was hydrolyzed under these conditions without DES pretreatment as the control group. The levels of sugars (glucose, xylose, fructose, sucrose, maltose and arabinose) and furans (furfural and 5-hydroxymethylfurfural (HMF)) in the samples were determined. ChCl:Gly (1:2) provided the highest fermentable sugar concentration as 56,48 g/L. Therefore, hydrolysate pretreated with ChCl:Gly (1:2) was used in the fermentation of Aspergillus niger A42 inulinase. To determine the effect of yeast extract ratio on inulinase activity, yeast extract was added to the hydrolysates at two levels, 1% and 5%. At a yeast extract ratio of 1%, the maximum inulinase and invertase activities were 120.56 U/mL and 68.91 U/mL, respectively. When the yeast extract ratio was increased to 5%, the maximum inulinase and invertase activities also increased to 364.88 U/mL and 475.69 U/mL, respectively. The results indicate that an increase in yeast extract ratio led to an increase in inulinase and invertase activities. Fermentations at 5% yeast extract were used to calculate the kinetic parameters. The fermentation process lasted for a period of 14 days, during which the rate of sugar consumption was determined to be 96.57%. The study found that the maximum sugar consumption rate was 22.62 g/L/day, which occurred between days 2-3. Additionally, the maximum inulinase production rate was calculated to be 145.50 U/mL/day, while the maximum invertase production rate was 157.95 U/mL/day. The total dry biomass concentration at the end of fermentation was determined to be 42.40 g/L. The final pH of the fermentation broth was determined to be 6.21. The maximum consumption rate was 14.78 g/L/day, occurring between the 3rd and 4th day of fermentation. The maximum inulinase production rate was 103.16 U/mL/day, and the maximum invertase production rate was 173.67 U/mL/day. The total dry biomass concentration at the end of fermentation was 53.00 g/L and the final pH of the fermentation broth was 6.07. In conclusion, deep eutectic solvent pretreatment was a successful application in the bioconversion of RB to inulinase enzyme.

KEYWORDS- Deep eutectic solvent pretreatment

- inulinase

- lignocellulosic biomass

- Aspergillus niger A42