JOURNAL 3118

Records of Agricultural and Food Chemistry

Year: 2024 Issue: 3 Special Issue: Abstracts 3rd. TCS, International Food Chemistry Congress February 29-March 03,2024 Antalya Türkiye

p.78 - 78

Viewed 1548 times.

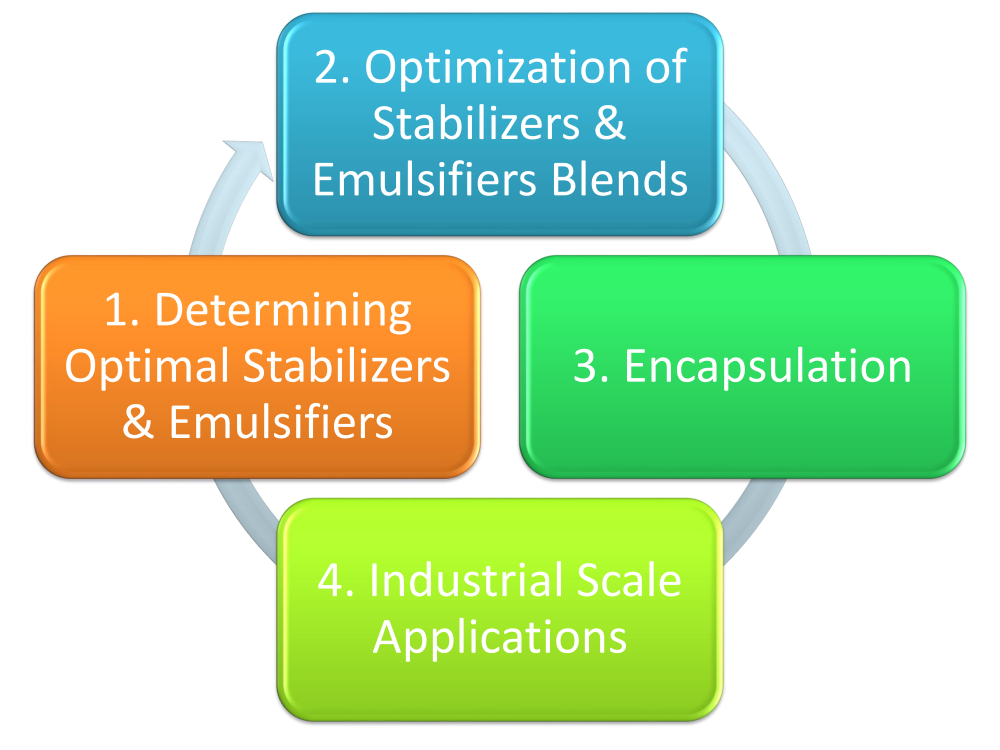

GRAPHICAL ABSTRACT

ABSTRACT

Given today's lifestyle, economic system, and technological and social structure, processed food products are frequently consumed, making the use of food additives necessary. Stabilizers and emulsifiers are used in food production to create the desired structure, and maintain or improve a certain structure, providing many benefits in food production and attracting more attention from producers. With the increasing consumption of ready-to-eat dairy desserts in recent years, this research aims to achieve a stable and high-quality final product in the industrial-scale production of pudding products. In the first stage of the study, the correct ratio of stabilizer and emulsifier mixture was determined to obtain a blend that would provide maximum efficiency and benefit. Particle size, zeta potential, and viscosity control analysis were conducted to stabilize the gums at the created recipes. This allowed the determination of the product's quality characteristics. In addition, a final product was produced and sensory evaluations were conducted with the target market's product. After the most suitable recipe content was determined as Xanthan gum, carrageenan, and monodiglycerides as fatty acids, in the second stage, Microfluidizer and ultrasound methods were tried for the homogeneous mixture of stabilizer-emulsifiers before encapsulation. After observing the adverse effects of high pressure on the product texture, different pressure applications were applied with the homogenizer, and the optimum pressure for reaching the target product was determined to be 30 mPa. In the encapsulation stage, the homogenized mixture was fed to the spray dryer, and drying parameters were determined. The optimum drying parameters were found to be an inlet temperature of 184 °C, outlet temperature of 75 °C, and product feeding temperature of 40 °C. The encapsulated product was then processed into the final product using a pilot UHT pudding application, and the quality parameters defined in the project were evaluated. It was observed that the encapsulated product yielded similar results to the target product.

KEYWORDS- Stabilizer

- emulsifier

- encapsulation

- pudding

- homogenization