JOURNAL 3119

Records of Agricultural and Food Chemistry

Year: 2024 Issue: 3 Special Issue: Abstracts 3rd. TCS, International Food Chemistry Congress February 29-March 03,2024 Antalya Türkiye

p.40 - 40

Viewed 1410 times.

GRAPHICAL ABSTRACT

ABSTRACT

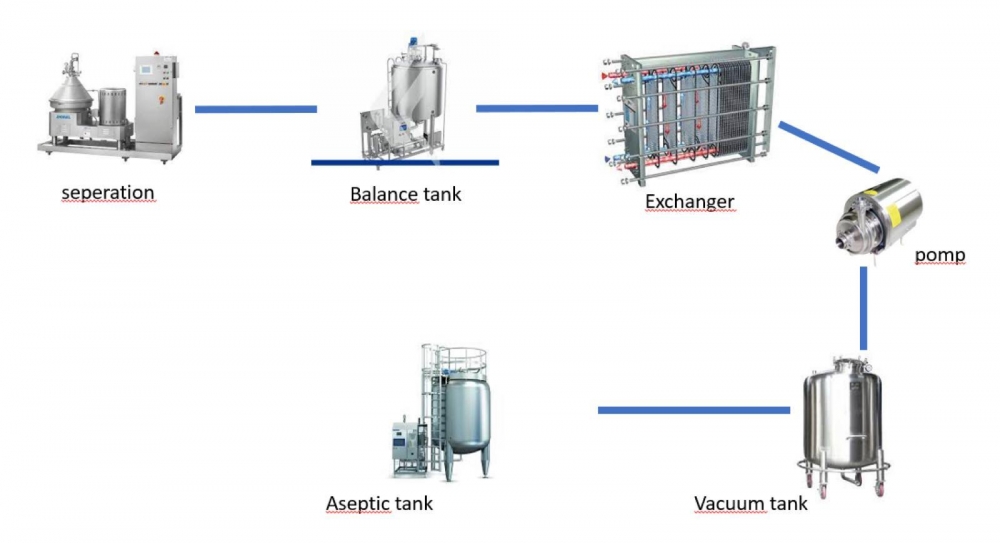

Milk is an important nutritional source with very high biological value. The most important biochemical parameters of milk include milk fat and protein. Milk protein and fat are also of great importance for the industry that processes milk. Cow’s milk contains 3.7-4.9% fat and 3.1-3.8% protein, depending on breed. According to the Turkish Food Codex Cream and Cream Communiqué, cream; It is defined as "the fat-rich emulsion of milk fat obtained by physical separation from milk in skim milk." Sterilization is one of these methods and, in general terms, is the process of destroying all living microorganisms (vegetative and spore forms) by chemical and physical methods. However, since there may be negative changes in the nutritional profiles of foods during this process, commercial sterilization norms are generally used to suit the food. Two different methods are used to sterilize milk in this way: direct and indirect. In the direct method, heat exchange is carried out between the milk and the steam mixed with the milk, while in the indirect method, plate or pipe heat exchangers are used. Direct method is divided into two: Steam-injection method and Steam-infusion method. In the steam injection method; The milk is first preheated to 80°C, then sent to the steam injection section via a pump, where steam is injected into it under pressure. In this section, water vapor gives its heat to the milk in a very short time, heating it to high temperatures such as 135-150°C. The milk is kept at this temperature for 2-4 seconds and is immediately taken into the vacuum tank, the water in it is evaporated with a sudden expansion under pressure and its temperature drops to 80°C. The vacuum in the vacuum tank is adjusted in such a way that the amount of water evaporated is equivalent to the amount of water previously mixed with the milk. After the sterilized milk is cooled to 80°C, it is homogenized, cooled to packaging temperature and packaged aseptically. In the steam infusion method; It is a UHT sterilization method applied by spraying milk into steam as a thin film. Drinking milk produced by this method is also called pulverized milk. Plate and tubular heat exchangers are used. As a homogenization method; It is an upstream (homogenization before heat treatment) and downstream (homogenization after heat treatment) method. Downstream is used in the direct system, and both upstream and downstream are used in the indirect system. In the production of cream and whipped cream, standard production direct (steam injection) and downstream are generally used. The purpose of this study is to investigate whether we can achieve the same product quality with different process methods. Scope of work; Different process parameters were evaluated in 35-fat animal cream, 18-fat animal cream, 33-fat vegetable fat cream and 26-fat whipped cream. Direct system-downstream, which is the standard production produced in the industry, and direct system downstream, indirect system downstream and indirect system upstream parameters produced in the pilot were evaluated by applying. The parameter we base the evaluation on is viscosity values. When the viscosity of 35 fat cream is examined; The indirect upstream process closest to the standard production direct downstream process was measured as 350-380 cp. When the viscosity of 18-fat cream is examined; The pilot production closest to the standard production direct downstream process was measured as 500-550 cp. When the viscosity of 33-fat herbal cream is examined; The indirect upstream process closest to the standard production direct downstream process is recorded as 200-220 cp. When the viscosity of 26-fat herbal whipped cream was examined; The indirect production downstream process closest to the standard production direct downstream process was measured as 120-140 cp. When the data is examined; It has been concluded that the viscosity ranges of all products comply with the standards. In conclusion; It has been concluded that different process parameters can produce positive results on products in order to produce products of the same quality, and in the light of these results, testing different process parameters in the industry can have positive results on product quality.

KEYWORDS- Cream

- process

- vicosity