JOURNAL 3042

Records of Agricultural and Food Chemistry

Year: 2024 Issue: 3 Special Issue: Abstracts 3rd. TCS, International Food Chemistry Congress February 29-March 03,2024 Antalya Türkiye

p.18 - 18

Viewed 1398 times.

GRAPHICAL ABSTRACT

ABSTRACT

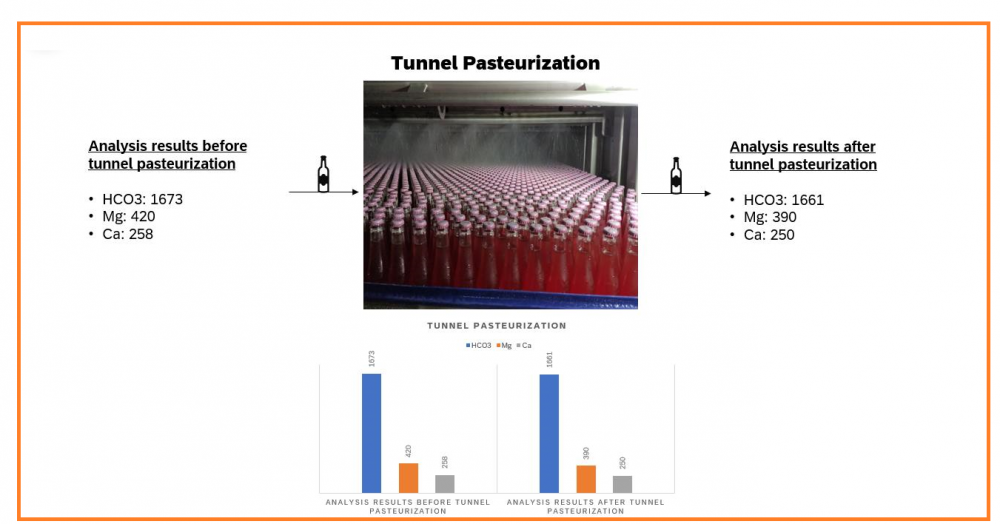

Tunnel pasteurization is a commonly preferred pasteurization method in the beverage industry. This method ensures the safe consumption of products by eliminating potential microorganisms in beverages. The process, which involves gradual temperature application, aims to effectively kill microorganisms by bringing the product, bottles, and caps to specific temperatures. Once the bottles enter the tunnel in tunnel pasteurization, they undergo preheating by exposure to water at 43-55°C. Subsequently, the pasteurization stage takes place at a temperature of 70-80°C, effectively killing microorganisms. Finally, a cooling process is carried out at 31-33°C, purifying the product from microorganisms. This process minimizes the risk of contamination while ensuring the safe consumption of the beverage. Flavored and fruit-flavored mineral waters entering the tunnel pasteurization system can lead to changes in calcium, magnesium, and bicarbonate minerals during the pasteurization process. To determine these potential mineral changes, detailed analyses are performed on samples taken before and after the flavored and fruit-flavored products. In a sample analysis, magnesium, calcium, and bicarbonate analyses were conducted on mineral water samples before and after tunnel pasteurization. The results indicated that tunnel pasteurization did not cause a significant decrease in magnesium, calcium, and bicarbonate values in mineral water, comparing the analysis results of samples taken before tunnel pasteurization and those taken at the tunnel pasteurization outlet. This finding demonstrates that tunnel pasteurization preserves product quality and ensures consumer safety [1].

KEYWORDS- Turnip juice

- fermentation

- lactic acid