JOURNAL 3092

Records of Agricultural and Food Chemistry

Year: 2024 Issue: 3 Special Issue: Abstracts 3rd. TCS, International Food Chemistry Congress February 29-March 03,2024 Antalya Türkiye

p.32 - 32

Viewed 1318 times.

-

Zehra Betül Ahi

-

Beyza Çay

-

Ayşegül Uzuner Demir

-

Mihriban Aydoğan-gemici

-

Buğrahan Özdemir

-

Saeid Choobdar Rahim

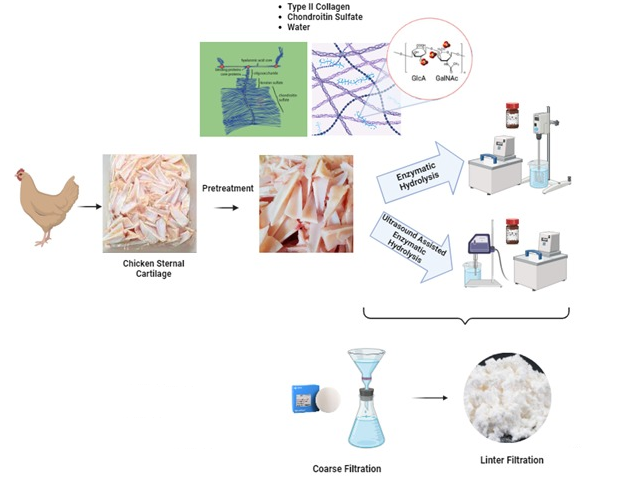

GRAPHICAL ABSTRACT

ABSTRACT

Osteoarthritis is a musculoskeletal disorder that is widely prevalent worldwide and is characterized by the deterioration and wearing down of joint cartilage. This condition leads to symptoms that significantly impact the quality of life, including pain, stiffness, and limited mobility [1]. Chondroitin sulfate (CS), a widely used glycosaminoglycan, is a popular dietary supplement for the treatment of osteoarthritis [2]. The beneficial effects of CS have been reported in osteoarthritis patients for joint pain, stiffness, and swelling. CS is a component of connective tissues and plays a significant role in numerous biological processes, such as supporting flexibility through its polyanionic structure, maintaining the structural integrity of cartilage, and preserving synovial fluid in the bone joints. Additionally, CS performs various functions in the human body, including the control of intracellular ions, preservation of connective tissues, management of osteoarthritis, protection of the cornea, nerve protection, anti-inflammatory properties, antiviral effects, anticancer activity, wound healing, and prevention of clotting [3]. The presented study aims to re-evaluate at least 6000 tons per year of generated cartilage waste in the poultry processing industry in Turkey. In the enzymatic extraction of the CS, chicken breast cartilage was processed using protease enzymes such as papain and alcalase which is the most used method due to the specificity of the protease. Additionally, enzymes like flavourzyme and neutrase, which target reactive groups in proteins, have been used to improve taste and aroma profiles. To increase the process efficiency and rapid release of chondroitin sulfate components, ultrasound-assisted extraction has been conducted during enzymatic hydrolysis. After the extraction, various purification steps were used to filtrate the solution containing chondroitin sulfate and Type II collagen such as coarse filtration, linter filtration to remove residual fat, and microfiltration to remove fine particles and bacteria. CA and type II collagen were separated by using membranes with different MWCO values in diafiltration, taking advantage of the difference in molecular weight. After obtaining CS and type II collagen hydrolysate separately, some characterization tests were conducted to specify their properties. The presence of chondroitin sulfate and Type II collagen obtained by diafiltration has been evaluated through tests such as FTIR and SDS-PAGE. The commercial chondroitin sulfate FT-IR spectrum shows peaks corresponding to sulfate at 856.9 cm-1. The peak at 1411.2 cm-1 represents C-O stretching vibration, variable angle OH vibration, and the presence of free COO- groups. The 1257.9 cm-1 and 1057.4 cm-1 peaks represent S=O and C-O-S stretching vibrations, respectively. SDS-PAGE analysis demonstrated specific bands at molecular weights corresponding to chondroitin sulfate (~37 kDa) and Type II collagen hydrolysate (~7.5 kDa) in the samples extracted with papain. The chemical characterization tests revealed a protein content of 46.29%, moisture content of 10.5%, and ash content of 23%. As a result of the study, CS was obtained successfully and has been confirmed through comparison with literature and commercial samples. The presented study aims to re-evaluate at least 6000 tons per year of generated cartilage waste in the poultry processing industry in Turkey. In the enzymatic extraction of the CS, chicken breast cartilage was processed using protease enzymes such as papain and alcalase which is the most used method due to the specificity of the protease. Additionally, enzymes like flavourzyme and neutrase, which target reactive groups in proteins, have been used to improve taste and aroma profiles. To increase the process efficiency and rapid release of chondroitin sulfate components, ultrasound-assisted extraction has been conducted during enzymatic hydrolysis. After the extraction, various purification steps were used to filtrate the solution containing chondroitin sulfate and Type II collagen such as coarse filtration, linter filtration to remove residual fat, and microfiltration to remove fine particles and bacteria. CA and type II collagen were separated by using membranes with different MWCO values in diafiltration, taking advantage of the difference in molecular weight. After obtaining CS and type II collagen hydrolysate separately, some characterization tests were conducted to specify their properties. The presence of chondroitin sulfate and Type II collagen obtained by diafiltration has been evaluated through tests such as FTIR and SDS-PAGE. The commercial chondroitin sulfate FT-IR spectrum shows peaks corresponding to sulfate at 856.9 cm-1. The peak at 1411.2 cm-1 represents C-O stretching vibration, variable angle OH vibration, and the presence of free COO- groups. The 1257.9 cm-1 and 1057.4 cm-1 peaks represent S=O and C-O-S stretching vibrations, respectively. SDS-PAGE analysis demonstrated specific bands at molecular weights corresponding to chondroitin sulfate (~37 kDa) and Type II collagen hydrolysate (~7.5 kDa) in the samples extracted with papain. The chemical characterization tests revealed a protein content of 46.29%, moisture content of 10.5%, and ash content of 23%. As a result of the study, CS was obtained successfully and has been confirmed through comparison with literature and commercial samples.

KEYWORDS- Chondroitin sulphate

- type II collagen hydrolysate

- diafiltration