JOURNAL 3098

Records of Agricultural and Food Chemistry

Year: 2024 Issue: 3 Special Issue: Abstracts 3rd. TCS, International Food Chemistry Congress February 29-March 03,2024 Antalya Türkiye

p.70 - 70

Viewed 1540 times.

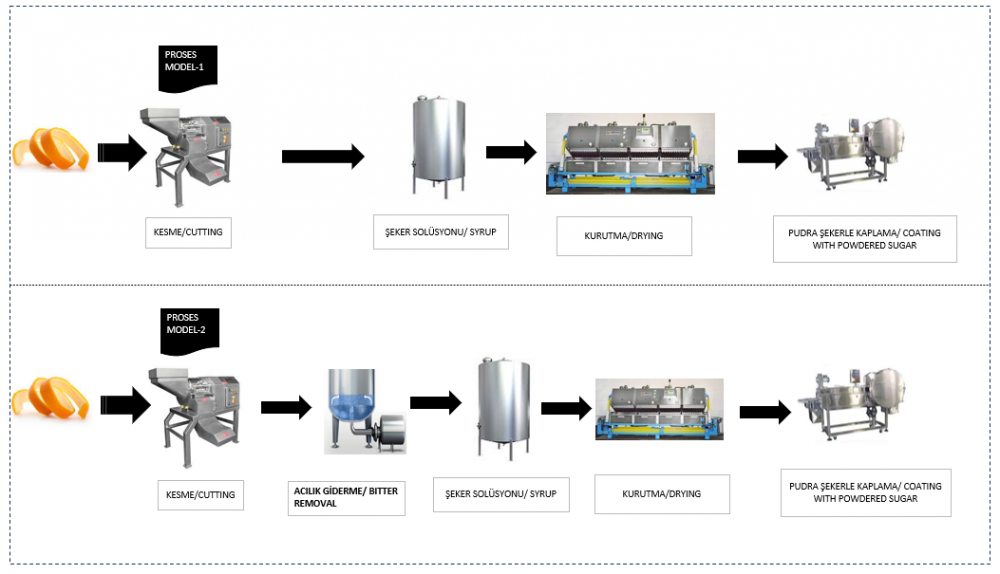

GRAPHICAL ABSTRACT

ABSTRACT

When considering the most studied topics in the field of food today, it can be observed that studies have increased in two main categories. One of them is the suitable process of by-products that are suitable for consumption but cannot be evaluated in terms of content, the other is the applications and processes to extend the shelf life of foods. Osmotic dehydration, the immersion of fruits in high concentration solutions to remove water, is a process that results in water loss. The balance of soluble solids transferred to fruits with the removed water is a preferred method for extending the shelf life of fruits, allowing the development of natural taste and the preservation of color, and providing protection in terms of microbiology. In recent times, studies have been carried out on the drying of fruits, vegetables, etc. foods with the osmotic dehydration method to increase shelf life. The essence of this method is the preservation of the freshness of fruits and vegetables by immersing cellular materials containing water in an osmotic solution. This results in the development of intermediate moisture products with lower water activity obtained by osmotic gain and water loss, which also supports improvements in taste profile. Chemical, physical, and biological activities that damage foods are significantly reduced during the process; thus, the shelf life of food products is extended. Osmotic dehydration is influenced by various factors such as osmotic agent, time and temperature, soluble solid concentration, solution/sample ratio, agitation, and material geometry. When evaluating food industry wastes, it is anticipated that the most waste occurs in fruit processing. Turkey is one of the rare countries where different varieties of fruits can be grown thanks to its fertile soils, vast agricultural areas, and favorable seasonal conditions. According to the Agricultural Economy and Policy Development Institute, oranges are the most grown and processed fruit. While 92 million tons of citrus fruits were produced worldwide in the 2019/20 production season, orange accounts for 50% of total citrus fruit production. In the 2020/21 production season, 9,500 tons of orange juice were produced from the oranges grown in Turkey. However, the peels were evaluated as having low added value. In this study, the drying process was carried out using the osmotic dehydration method on orange peels to obtain confections. Two different processes were studied, and the first process was carried out with partial revisions to the method applied in the literature [5]. In the second process, an acidity removal process was applied for better taste and texture results due to the bitterness of the orange. According to the results obtained, while no significant difference was observed in color, appearance, brix, and process time, when the taste parameter was evaluated, the process made by removing bitterness was deemed consumable by the panelists. As a result of the study, a solution of 1/2 sugar, 8-10 hours of time, and temperatures of 50-60°C were found to be suitable; especially, it was determined that the pre-treatment of removing bitterness should be performed. As a result of this study, the by-product of the process was transformed into a value-added product.

KEYWORDS- Orange peel

- osmotic dehydration

- infusion

- drying