JOURNAL 3100

Records of Agricultural and Food Chemistry

Year: 2024 Issue: 3 Special Issue: Abstracts 3rd. TCS, International Food Chemistry Congress February 29-March 03,2024 Antalya Türkiye

p.71 - 71

Viewed 1392 times.

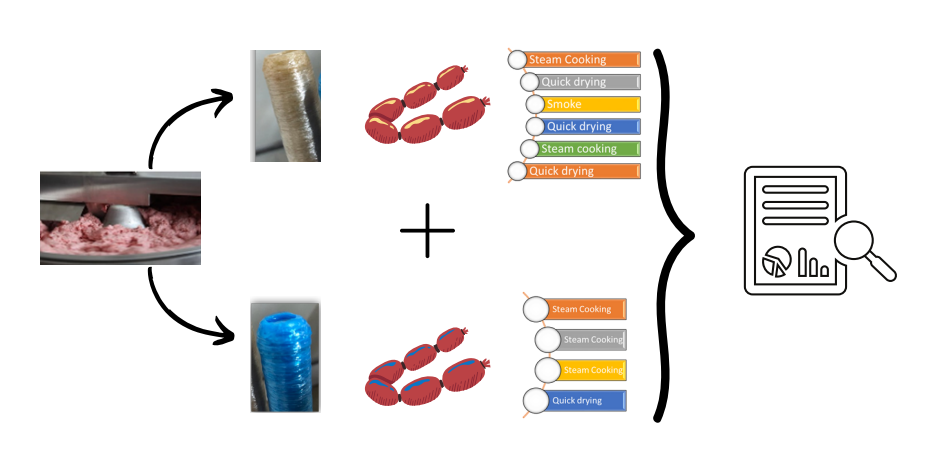

GRAPHICAL ABSTRACT

ABSTRACT

Nowadays, resource efficiency is critical for sustainability. This study investigates the use of high moisture barrier plastic casing as an alternative to traditional cellulose casing in sausage production, based on various innovative initiatives for sausage production by many casing suppliers. The plastic casing significantly reduces water loss during processing, leading to positive environmental and economic impacts. Various parameters including texture, shelf life, color analysis, and casing durability were examined. Results show no significant differences in chemical composition between products with plastic casing and those with traditional casing. However, texture analysis revealed differences, particularly in adhesiveness and springiness. Significant color variations were also observed. The study anticipates substantial water savings and energy conservation through the use of plastic casing, with a projected reduction in water consumption of 3,680 tons per month and energy savings of 1.36 kWh/ton through oven program optimization. This study demonstrates that the high moisture barrier polyamide casing can be used as an alternative.

KEYWORDS- Cellulose Casing

- moisture barrier

- polyamide Casing

- Sausage formulation

- plastic Casing

- process parameters