JOURNAL 3102

Records of Agricultural and Food Chemistry

Year: 2024 Issue: 3 Special Issue: Abstracts 3rd. TCS, International Food Chemistry Congress February 29-March 03,2024 Antalya Türkiye

p.72 - 72

Viewed 1316 times.

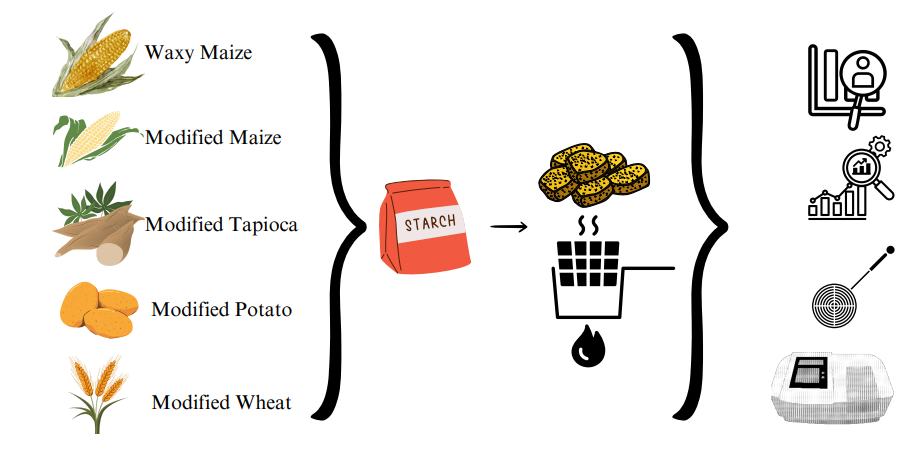

GRAPHICAL ABSTRACT

ABSTRACT

When preparing coated mixtures, the production involves coating, frying, and cooking stages. During these stages, deep frying in oil is a fundamental process that affects the surface parameters of the coated product. Deep frying in oil above the boiling point of water (150-160°C) is maintained for approximately 25-30 seconds, resulting in rapid evaporation of water due to the formation of a crust on the product surface, hindering the escape of steam. Accumulated intense steam creates cracks in the crust, allowing steam to escape, along with oil absorption. Gelatinization of starch components occurs during this process. Starch consists of intertwined amylose and amylopectin. These spiral shapes, with hydrophobic interiors and hydrophilic exteriors, facilitate the formation of complexes of lipids with hydrophobic cavities. Particularly, the use of starches with high amylopectin content has been observed to enhance crispiness in coated products. While high-amylose corn starch contains 85% amylose, the amylopectin content in waxy corn is 99%. This study examines the product texture properties, lipid peroxidation value (TBARS), oil absorption rates during frying, and sensory analysis values of commonly used starch types in the industry (waxy corn, modified corn, modified tapioca, modified wheat, and modified potato starches). Significant differences were observed in texture, oil absorption during frying, and sensory analysis results (appearance, color, texture, crispiness, greasiness, flavor, overall acceptance) (p=0.05) among the starch types, whereas no significant difference was observed in peroxidation values. According to the data obtained from the texture analyzer, products made using modified corn and waxy corn starches exhibited better crispiness, brittleness, hardness, and chewiness parameters compared to other starch types. In sensory analysis results, various parameters were found to be weaker in starches other than waxy corn starch. When comparing oil absorption rates during deep frying, modified tapioca absorbed the most oil, while waxy corn absorbed the least, with no significant difference observed among other starch types (p=0.05). Based on this study, it is anticipated that modified corn and waxy corn starches may provide advantages over other evaluated starch types in terms of both structural and oil absorption properties. This presumption could be attributed to the high amylopectin content, although it requires support from microscale analyses.

KEYWORDS- Starch

- deep Frying

- coating

- poultry

- further process

- meize